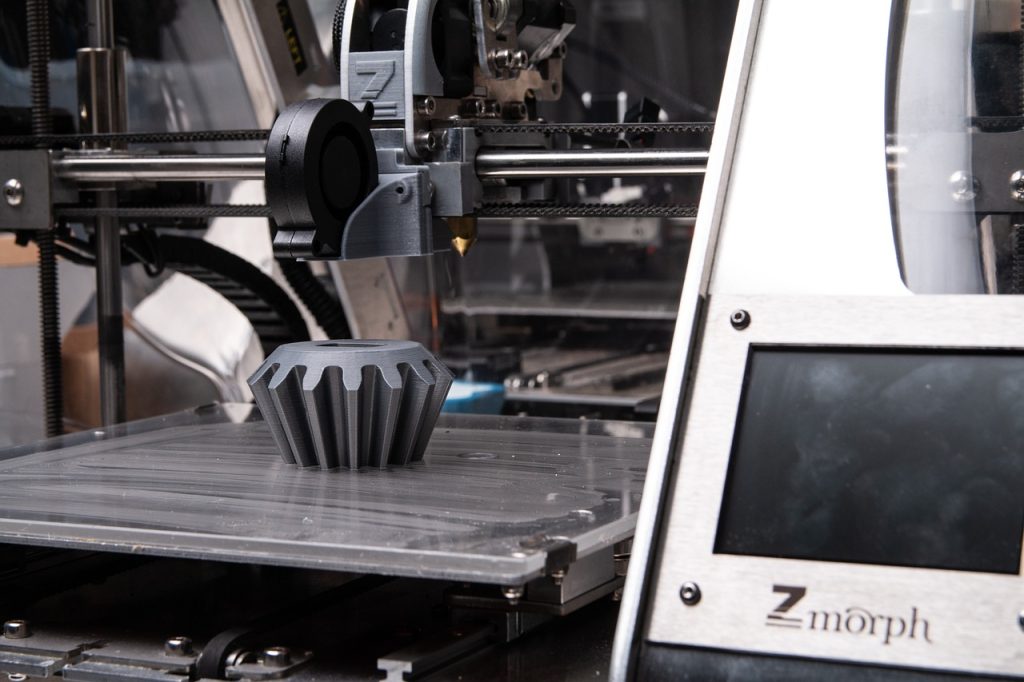

Diving into 3D printing is exciting, but it can also come with its fair share of challenges. Beginners often face common pitfalls that can lead to wasted time, filament, and frustration. Here are the top 10 mistakes new makers make—and how you can avoid them to achieve better prints from the start.

1. Skipping Bed Leveling

An unlevel bed is one of the most common causes of failed prints.

How to Avoid It:

- Always level the bed before starting a print.

- Use a piece of paper or a feeler gauge to ensure the nozzle is just the right distance from the bed.

- Consider upgrading to an auto-bed-leveling sensor if your printer supports it.

2. Ignoring First Layer Adhesion

The first layer sets the foundation for the entire print. Poor adhesion leads to prints detaching mid-job.

How to Avoid It:

- Clean the build plate with isopropyl alcohol to remove dust and grease.

- Use adhesives like glue sticks, painter’s tape, or PEI sheets for better grip.

- Check your slicer settings to ensure the first layer height and speed are optimized.

3. Using the Wrong Print Settings

Default slicer settings might not be ideal for every project.

How to Avoid It:

- Adjust layer height, infill, and print speed based on your model’s needs.

- Experiment with different settings on small test prints before committing to large jobs.

- Research recommended settings for your specific filament type.

4. Not Calibrating the Printer

Poor calibration results in dimensional inaccuracies and subpar print quality.

How to Avoid It:

- Calibrate your printer’s extruder, axis steps, and flow rate regularly.

- Print calibration tests like the “XYZ calibration cube” to verify accuracy.

- Use tools like digital calipers to measure and adjust accordingly.

5. Ignoring Filament Quality

Cheap or improperly stored filament can ruin prints.

How to Avoid It:

- Invest in reputable filament brands.

- Store filament in a dry, sealed container with silica gel packs to prevent moisture absorption.

- Use a filament dryer if your material has been exposed to high humidity.

6. Overlooking Supports

Not adding supports when needed can cause drooping or failed overhangs.

How to Avoid It:

- Use your slicer’s “preview” mode to identify areas that need supports.

- Experiment with different support settings (e.g., grid vs. tree supports).

- Remove supports carefully to avoid damaging your model.

7. Printing Too Fast

High speeds can cause under-extrusion, layer shifting, and poor print quality.

How to Avoid It:

- Start with moderate speeds (50-60 mm/s) and adjust based on results.

- Reduce speed for intricate models or when printing with flexible materials.

8. Neglecting Nozzle Maintenance

A clogged or dirty nozzle can disrupt prints and waste filament.

How to Avoid It:

- Clean the nozzle regularly with cleaning filament or a needle.

- Replace the nozzle if wear or clogs persist.

- Avoid switching filament types without properly purging the extruder.

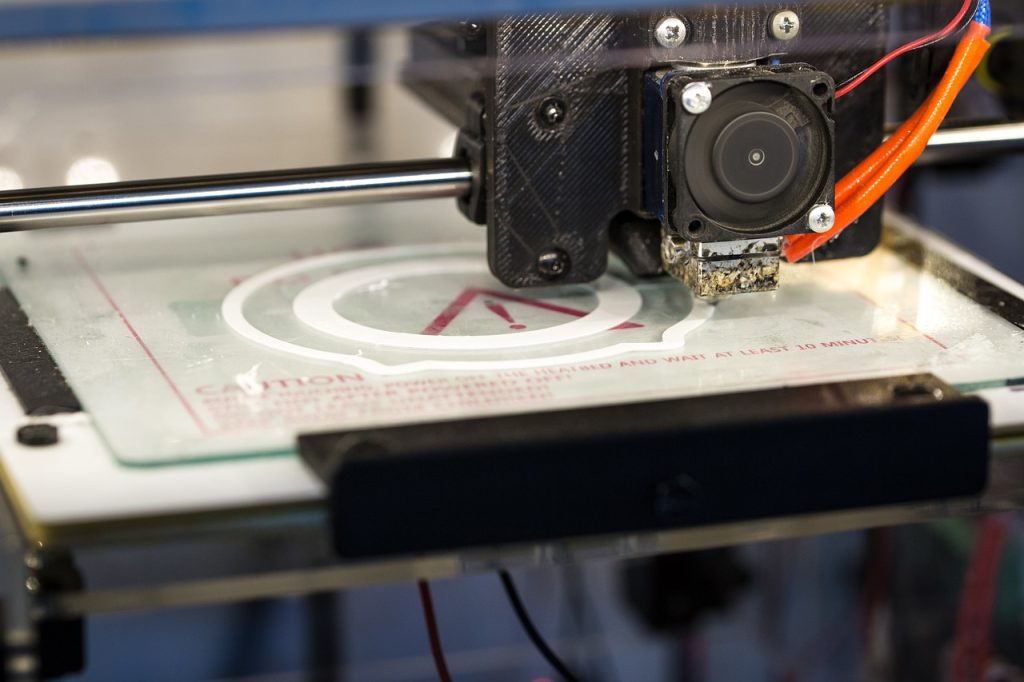

9. Underestimating the Importance of Cooling

Insufficient cooling can lead to stringing, sagging, or poor layer adhesion.

How to Avoid It:

- Ensure your printer’s cooling fan is working correctly.

- Adjust cooling settings in your slicer based on the filament (e.g., PLA requires more cooling, while ABS benefits from less).

- Use a fan shroud for better airflow distribution.

10. Not Reading the Manual

Many issues arise from skipping the printer’s user manual.

How to Avoid It:

- Read the manual to understand your printer’s specific features and setup instructions.

- Join online communities or forums for advice on your specific printer model.

- Watch tutorials to learn tips and tricks for optimizing your workflow.

Conclusion

Mistakes are a natural part of learning, but being aware of these common pitfalls can help you avoid unnecessary frustration. With a bit of patience, practice, and the right knowledge, you’ll be creating high-quality prints in no time.

Do you have a favorite 3D printing tip? Share it in the comments below—we’d love to hear from you!